Rumored Buzz on Stainless Steel Infill Panel

Table of ContentsRumored Buzz on Stainless Steel Infill PanelSome Known Incorrect Statements About Stainless Steel Infill Panel

Insulated infill panels typically contain an inside and also outside skin (aluminum or steel) laminated flooring to any variety of substrates. These substrates/skins after that sandwich a shielding core to provide you a 5-ply panel prepared to be polished right into the frame. One of the most frequently utilized substratum is toughened up hardboard, which has been thought about a sector criterion for greater than 50 years. Nevertheless, over the last two decades, there has been an increase in various other substrate materials. These consist of, but are not restricted to: Fiber Reinforced Cement Board (which is a Course A, non-combustible material) Corelite (or corrugated plastic, a lightweight product that offers a greater degree of wetness resistance) Gypsum Board (which is used to satisfy fire codes when used as the interior substratum) And most recently, strong plastic (or ABDOMINAL MUSCLE board).

The features of an infill panel are as provided previously for cladding panels in basic. Infill panels are lightweight as well as typically glazed to offer great inner natural day lighting conditions. Various from cladding wall since infill panels is dealing with between framework in the framed framework. The panel design can be so prepared to expose some or all of the structural members producing various optical impressions. For example, if horizontal panels are made use of, leaving just the beam of lights exposed, an illusion of extra size and/or decreased elevation can be created. The design need infill panel walls are:1) lightweight2) resistance to fire3) heat loss4) high durability5) rigid6) much less maintenance7) sound penetration8) interstitial condensation A large selection of products or combinations of materials can be used such as lumber, steel, light weight aluminum and also plastic.

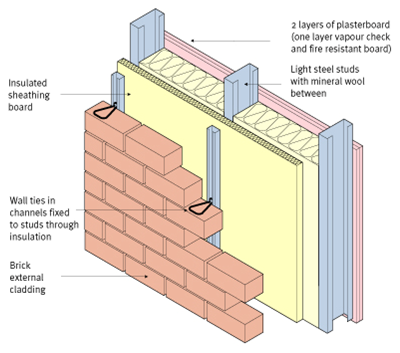

The glazing component ought to be such that a practical thickness of glass can be specified (stainless steel infill panel). The jointing trouble with infill panels happen generally at its joint with the architectural structure as well as allocation for dampness or thermal movement is usually achieved by utilizing a suitable mastic or sealer. Masonry infill panels of contemporary cavity building can be used to maintain traditional functions and to acquire high standards of audio as well as thermal insulation as well as fire protection. Stonework walls are connected to the architectural framework with wall connections cast right into the concrete columns or with a purpose-made cladding support system. Many infill panels are provided as a producer's modular system, given that purpose-made panels can be uneconomic, however whichever technique is selected the layout aims continue to be consistent; that is, to supply a panel which fulfils all the called for functions and also has a reduced lasting maintenance aspect.

One of the maintenance troubles encountered with infill panels as well as possibly to a lesser level with the concrete cladding, is the cleaning of the faade and particularly the glazing. All structures accumulate dust, the impacts of which can vary with the material: concrete and also stonework have a tendency to accept dust and weather condition all-natural, whereas impervious products such as metals as well as glass do decline and also can wear away or end up being less effective. If glass is allowed to become covered with dirt its visual appearance is much less appropriate, its optical efficiency lessens since clearness of vision is lowered as well as the valuable penetration of all-natural daylight decreases.

The Of Stainless Steel Infill Panel

Access for cleaning glazed areas can learn this here now be outside or Get More Information inner. Windows at ground level present no access problems and present just the concern of option of method such as hand cloths or telescopic posts with squeegee heads. Reduced as well as medium-rise structures can be gotten to by ladders or a mobile scaffold tower and typically present extremely couple of problems. High-rise structures need mindful factor to consider. Exterior access to windows is obtained by using a cradle suspended from roof covering level; this can be in the type of a short-term system including counterweighted cantilevered beams where the cradle is suspended. Permanent systems, which are integrated as component of the building design, are a lot more effective and also contain a track on which a mobile cart is installed and from which davit arms can be predicted beyond the roof side to support the cradle.

Internal accessibility for cleaning the outside glass face can be achieved by utilizing home windows such as reversible sashes, straight and vertical gliding sashes, but the developer is limited in his option to the reach possible by the ordinary person. It can not be overemphasized that such home windows can be a very dangerous threat unless carefully made to ensure that all parts of the polished location can be reached click here to find out more by the person cleansing the windows while standing securely on the floor. Intro The functions of an infill panel are as detailed previously for cladding panels generally. Infill panels are light-weight and typically polished to give excellent interior all-natural day illumination problems (stainless steel infill panel).