The Aluminium Infill Panels Statements

Table of ContentsNot known Incorrect Statements About Aluminium Infill Panels Some Known Questions About Aluminium Infill Panels.Everything about Aluminium Infill Panels

As a designer put it, in picking the core material for a sandwich panel "I only make use of the mineral wool ones due to the fact that your intestine tells you it is not ideal to cover a building in plastic". In 2000 Gordon Cooke, a leading fire safety professional, reported that "the usage of plastic foam cored sandwich panels ... is hard to warrant when thinking about life security". He stated the panels "can add to the intensity as well as rate of fire growth" and also this has actually caused "enormous fire losses". Style of a cavity in between the cladding and also the exterior wall of the structure (or its sheath of insulation) is also considerable: flames can occupy the tooth cavity and also be drawn upwards by convection, lengthening to develop second fires, and do so "no matter the materials used to line the dental caries".

Thomsen, O. T.; Bozhevolnaya, E.; Lyckegaard, A. (2005 ). Springer. ISBN 978-1-4020-3444-2. Aly, Mohamed F.; Hamza, Karim T.; Farag, Mahmoud M. (April 2014). "A products choice procedure for sandwiched beams through parametric optimization with applications in auto sector". Products & Design (1980-2015). 56: 219226. doi:10. 1016/j. matdes. 2013. 10.075. " Gorcell by Renolit". Renolit. com. Fetched 3 October 2014. " Stinger honeycomb panel". coroplast. com. Archived from the initial on 27 October 2012. Fetched 3 October 2014. " Packaging sandwich panels". Karton. it. Gotten 3 October 2014. Yazdani Sarvestani, H.; Akbarzadeh, A.H.; Niknam, H.; Hermenean, K. (September 2018). "3D printed architected polymeric sandwich panels: Energy absorption as well as structural efficiency".

Getting The Aluminium Infill Panels To Work

200: 886909. doi:10. 1016/j. compstruct. 2018. 04.002. Azzouz, Lyes; Chen, Yong; Zarrelli, Mauro; Pearce, Joshua M.; Mitchell, Leslie; Ren, Guogang; Grasso, Marzio (April 2019). " Mechanical residential or commercial properties of 3-D printed truss-like lattice biopolymer non-stochastic frameworks for sandwich panels with all-natural fibre composite skins" (PDF). Compound Frameworks. 213: 220230. doi:10. 1016/j. compstruct. 2019. 01.103. Sugiyama, Kentaro; Matsuzaki, Ryosuke; Ueda, Masahito; Todoroki, Akira; Hirano, Yoshiyasu (October 2018). "3D printing of composite sandwich structures utilizing continual carbon fiber and fiber stress". Compounds Part A: Applied Scientific Research and also Manufacturing. 113: 114121. doi:10. 1016/j. compositesa. 2018. 07.029. Zhang, Xiaoyu; Zhou, Hao; Shi, Wenhua; Zeng, Fuming; Zeng, Huizhong; Chen, Geng (October 2018).

Fetched 15 June 2017. Rajaneesh, A.; Sridhar, I.; Akisanya, A.R. (January 2016). "Impression failure of round composite sandwich plates". Materials & Layout. 89: 439447. doi:10. 1016/j. matdes. 2015. 09.070. hdl:. Rajaneesh, A.; Sridhar, I.; Rajendran, S. (March 2014). "Relative performance of steel and polymeric foam sandwich plates under low rate effect". International Journal of Influence Engineering. 65: 126136. doi:10. 1016/j. ijimpeng. 2013. 11.012. Rajaneesh, A.; Satrio, W.; Chai, G.B.; Sridhar, I. (April 2016). "Lasting life prediction of woven CFRP laminates under 3 factor flexural exhaustion". Composites Part B: Engineering. 91: 539547. doi:10. 1016/j. compositesb. 2016. 01.028. Rajaneesh, A.; Sridhar, I.; Rajendran, S.

A Biased View of Aluminium Infill Panels

" Failing mode maps for circular composites sandwich plates under flexing". International Journal of Mechanical Sciences. 83: 184195. doi:10. additional hints 1016/j. ijmecsci. 2014. 03.029. Organization of British Insurers (May 2003). " Technical rundown: fire efficiency of sandwich panel systems" (PDF). Booth, Robert; Sample, Ian; Pegg, David; Watt, Holly (15 June 2017). " Professionals cautioned government versus cladding material used on Grenfell". The Guardian. Gordon M E Cooke (November 2000). " Sandwich panels for external cladding fire safety problems and also effects for the risk evaluation process" (PDF). Probyn Miers (Winter Months 2016). " Fire Dangers From External Cladding Panels A Point Of View From The UK". Point of view. (3. 3.2 Cavities).

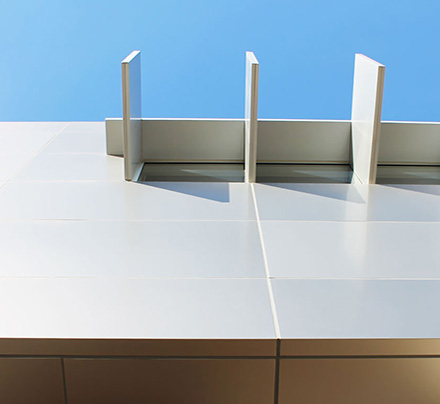

Aluminium composite material panel structure A sandwich panel is any type of structure made from three layers: a low-density core, and also a thin skin-layer bonded to each side. Sandwich panels are used in applications where a mix of high structural rigidness as well as low weight is needed - aluminium infill panels. The architectural capability of a sandwich panel resembles the timeless I-beam, where 2 face sheets primarily withstand the in-plane as well as lateral bending loads (comparable to flanges of an I- light beam), while the core material primarily stands up to the shear loads (similar to the internet of an I-beam). The idea is to make use of a light/soft but thick layer for the core and also strong however slim layers for face sheets.

Sandwich panels are an instance of a sandwich structured composite: the strength as well as agility of this innovation makes it popular as well as widespread. Its convenience indicates that the panels have many applications as well as come in numerous kinds: the core and skin materials can differ widely as well as the core might be a honeycomb or a solid filling (aluminium have a peek at these guys infill panels). Confined panels are called cassettes. Epcot's Spacecraf Planet is an example of using ACP in style. It is a geodesic sphere composed of 11,324 ACP ceramic tiles. One obvious application remains in airplane, where mechanical performance as well as weight-saving are important. Transportation and automotive applications additionally exist.